< Previous | Contents | Next >

Section 1 General

102. Matters to be approved

"deemed appropriate by the Society" referred in 102. 2 of the Rules means where it is applicable for the other materials and welding than the specified ones in Pt 2 of the Rules.

103. Special weldings

Production weld test for tanks of ships carrying liquefied gases in bulk, and tank circumference hull construction units.

1. Application

When welding is made for independent tanks of ships carrying liquefied gases in bulk, the pro- duction weld tests are to be carried out for each position of welding in accordance with the fol- lowing requirements, in addition to the welding procedure qualification tests specified in Ch 2, Sec. 4 of the Rules.

(1) For Type A independent tanks, the production weld test is to be carried out on at least one test sample for every 50 m of welding length of butt joints of principal structural members.

However, consideration may be given for reduction of the number of test sample or omission of the production weld test by taking into account the past records and the actual state of quality control system of the manufacturer.

(2) For Type B independent type tanks, the production weld tests are to be carried out on at least one test sample for every 50 m of welding length of butt joints of principal structural

members. However, the number of test sample may be reduced to one test sample for every

100 m of

welding length by taking into account the past records and the actual state of quality control

system of the manufacturer. In this case, however, at least one or more test specimens are to be selected for one tank.

(3) For Type C independent type tanks, the production weld tests are to be carried out on at least

one test sample for every 30 m of welding length of butt joints of principal structural members. However, the number of test sample may be reduced to one test sample for every 50 m of

system of the manufacturer.

Remark : The definitions of type A, B and C independent tank comply with the requirements in the Pt 7, Ch 5, 402. 4 of the Rules.

2. Test procedure

(1) The production weld tests are to be carried out for every welding length specified in the above

1. for welded joints made under the same welding procedure, position of welding and welding conditions.

(2) Test samples are, in principle, to be located on the same line as the welded joints of the body and to be welded at the same time of welding of the body.

3. Kind of test

Kinds of the test are to be as given in Table 2.2.1 of the Guidance.

![]()

Table 2.2.1 Kind of Test

Material | Kind of Test |

9 % Ni steel | Tensile test, bend test and impact test |

Stainless steel | Tensile test and bend test |

Aluminium alloys | Tensile test and bend test |

Steel for low temperature service (excluding 9 % Ni steel) | Tensile test, bend test and impact test |

![]()

4. Test assemblies

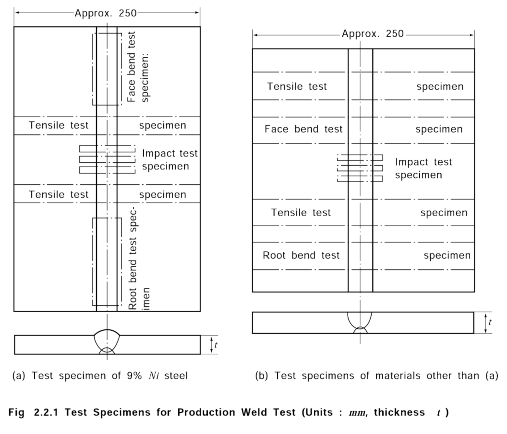

The shape and size of test assemblies are to be as shown in Fig 2.2.1 of the Guidance. In cases of Type A and Type B independent tanks, tensile test may not be required.

5. Test specimens

(1) The shape and size of tensile test specimens

Table 2.2.1 of the Rules.

are to be of the R 2A test specimen specified in

(2) The shape and size of bend test specimens are to be of the R B 1 or R B 2 test specimens speci-

fied in Table 2.2.2 of the Rules. For test specimens with a thickness exceeding 19 mm, side bend test specimens are to be substituted for face bend and root bend test specimens.

(3) Impact test specimens are to be the R4 test specimen specified in Table 2.1.3 of the Rules.

In the impact test, one set of test specimens comprising three pieces are to be taken from every

test assembly. The test specimens are to be taken alternately from the position "a" and from a position among "b" through "e" where the lowest value is recorded in the welding procedure

qualification test, shows in Fig 2.2.7 of the Rules. This means that one set of three test speci-

mens are taken from a test assembly at the position "a", hence other set of three test specimens are taken in the subsequent test assembly from the position among "b" through "e" where the

lowest value is recorded, and this procedure is repeated. No impact test specimens is required in cases of stainless steel and aluminium alloy.

6. Tensile test

(1) The tensile strength of 9 % Ni steels is to be 630 ![]() or more.

or more.

(2) The tensile strength of stainless steels, aluminium alloys and steels for low temperature service

(excluding 9 % Ni steels) is to be more than the specified value of the base metal.

7. Bend test

(1) The bend test specimen is to be bent up to an angle of 180 〫 by a test jig with an inner radi- us of double (three and a third times for aluminium alloys) the thickness of the test specimen.

(2) The results of the bend test are to be as free from cracks exceeding 3 mm in length in any di-

rection on the outer bent surface and from other significant defects.

![]()

26 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

8. Impact test

The specified values for the impact test are as given in

Table 2.2.8

of the Rules.

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 27

![]()